English

Tel:+0086 133 9331 8107

Mail:sales06@yppetro.com

Mail:sales06@yppetro.com

Professional oil drilling rig equipment sales.

| SKU: | |

|---|---|

| Availability: | |

| PDF Export | |

Product Description

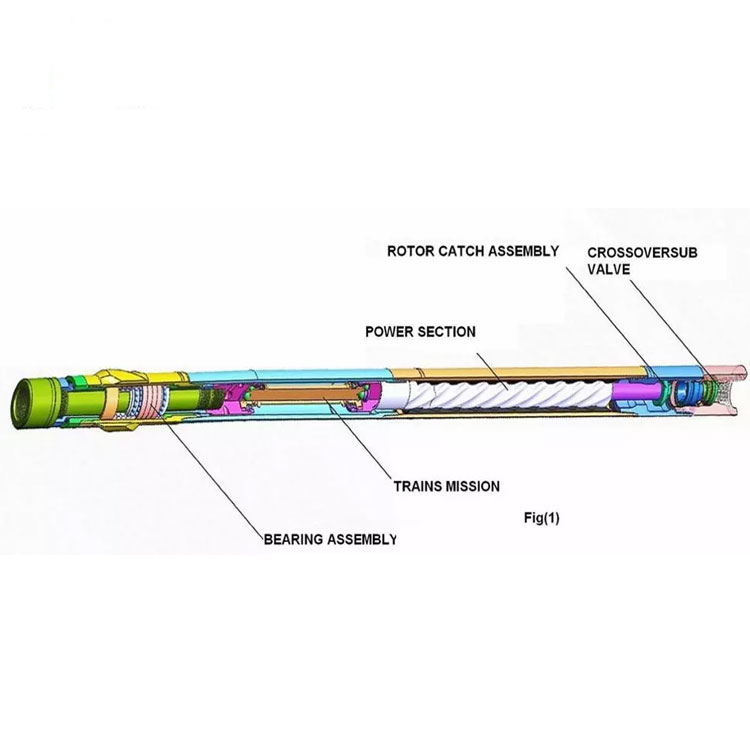

(1) Float assembly or By-pass valve assembly

(2) Rotor anti-drop assembly

(3) Power section assembly

(4) Universal shaft assembly

(5) Bearing assembly

In addition to ordinary downhole motor, the following components for special purpose are available to make up steerable downhole motor to meet various requirements of drilling operation:

(1) Directional joint

(2) Bend joint (fitted above or below by- pass

valve to make up single or double bend downhole motor)

(3) Hollow by-pass power section

(4) Fixed Bend Housing (with 0~3°fixed angle)

(5) Adjustable bend housing

(6) Housing stabilizer on bearing assembly

(7) Changeable stabilizer

downhole drilling motor

(Some Models are here for your reference, more models and deatils pls contact us.)

(Of course, customization is also allowable, as long as you can provide detailed drawing, especially some parts like bearings.)

Each downhole mud motor is tested on the professional testing bench and the delivered downhole mud motor is 100% guarateed qualitified, then the test report will be provided to you.

Each downhole mud motor can continuously work 7~10 days with good working condition and correct operation.

Of course, online after-sale service is also available at any time.

Type | 5LZ73 7.0 | 5LZ89 7.0 | 5LZ95 7.0 | 7LZ95 3.5 | 9LZ95 7.0 | 5LZ120 7.0 | |

Hole Size | Mm | 95~121 | 114~152 | 118~152 | 118~152 | 118~152 | 149~200 |

In | 33/4~43/4 | 41/2~6 | 45/8~6 | 45/8~6 | 45/8~6 | 57/8~77/8 | |

Thread Type | Top | 23/8"REG | 23/8"REG | 27/8"REG | 27/8"TBG | 27/8"REG | 31/2"REG |

Bottom | 23/8"REG | 23/8"REG | 27/8"REG | 27/8"REG | 27/8"REG | 31/2"REG | |

Nozzle pressure drop | Mpa | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~3.5 | 1.4~7 | 1.4~7 |

Recommend Flow | L/S | 3~8 | 3~8 | 7~12 | 7~11 | 6~10 | 9~14 |

Bit rotary | R/Min | 109~291 | 95~200 | 90~195 | 120~240 | 90~200 | 95~200 |

Motor pressure drop | Mpa | 2.4 | 2.4 | 3.2 | 2.4 | 2.4 | 3.2 |

Working torque | N.M | 460 | 628~838 | 1260~1630 | 723~960 | 750~1020 | 1480~1820 |

Lagging torque | N.M | 650 | 1300 | 2200 | 1500 | 1550 | 2440 |

Output power | KW | 4.7~12.5 | 7.3~15.3 | 13.6~29.5 | 18~24 | 8.3~18.5 | 16.4~34.5 |

Recommended bit weight | T | 4.7~12.5 | 2.0 | 2.5 | 1.0 | 2.5 | 3 |

Max bit weight | T | 2.5 | 3.0 | 5 | 1.5 | 5 | 5 |

Length | Straight | 3450 | 3570 | 4450 | 2500 | 3590 | 5085 |

Single curve | 3450 | 4675 | 3590 | 5335 | |||

Weight | Straight | 100 | 98 | 140 | 89 | 120 | 390 |

Single curve | 102 | 150 | 120 | 420 | |||

Type | 5LZ165 7.0 | 5LZ165 7.0 | 5LZ172 7.0 | 5LZ197 7.0 | 5LZ210 7.0 | 5LZ244 7.0 | |

Hole Size | Mm | 213~251 | 213~251 | 213~251 | 251~311 | 251~375 | 311~445 |

In | 83/8~97/8 | 83/8~97/8 | 83/8~97/8 | 97/8~121/4 | 97/8~143/4 | 121/4~171/4 | |

Thread type | Top | 41/2"REG | 41/2"REG | 41/2"REG | 51/2"REG | 65/8"REG | 65/8"REG |

Bottom | 41/2"REG | 41/2"REG | 41/2"REG | 65/8"REG | 65/8"REG | 75/8"REG | |

Nozzle pressure drop | Mpa | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 |

Recommend Flow | L/s | 20~28 | 20~28 | 25~35 | 25~57 | 35~50 | 50~75 |

Bit rotary | R/min | 90~160 | 80~150 | 90~160 | 86~196 | 100~160 | 100~160 |

Motor pressure drop | Mpa | 2.4 | 3.2 | 4.0 | 4.0 | 4.0 | 4.0 |

Working torque | N.m | 2750~3960 | 3860~4980 | 5860~6970 | 7800~9350 | 9980~11900 | 12870~13970 |

Lagging torque | N.m | 6300 | 8470 | 11550 | 18690 | 19600 | 23000 |

Output power | Kw | 31.6~56.2 | 37~69.4 | 60.4~107.4 | 70~160 | 115~183 | 140~225 |

Recommended bit weight | T | 8 | 8 | 10 | 16 | 17 | 18 |

Max bit weight | T | 16 | 16 | 16 | 24 | 28 | 30 |

Length | Straight | 5930 | 6830 | 7230 | 8470 | 8400 | 9060 |

Single curve | 6180 | 7080 | 7480 | 8720 | 8660 | 9320 | |

Weight | Straight | 742 | 820 | 930 | 1140 | 1460 | 1980 |

Single curve | 772 | 850 | 970 | 1195 | 1520 | 2050 | |

For unparalleled performance in HDD, oil, gas, and coiled tubing applications, trust Yppetro's API 7-1 Downhole Drilling Mud Motor. Engineered to exceed industry standards, our mud motors deliver reliability and efficiency when you need it most. Choose Yppetro for your drilling needs and experience the difference in quality and performance!